Overview

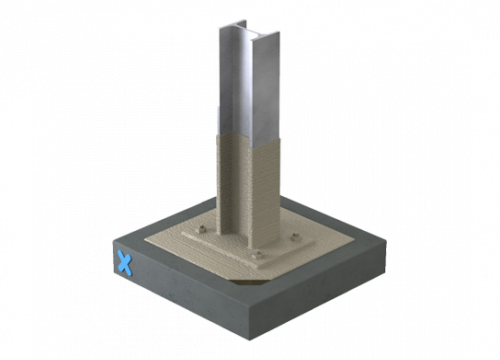

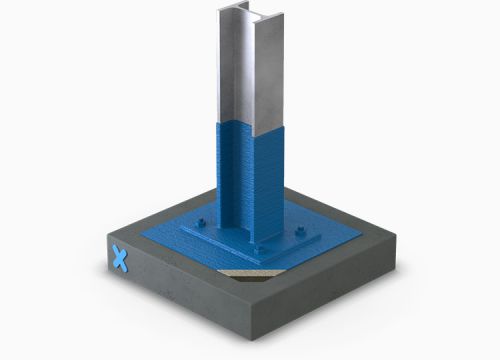

Details and penetrations which are highly complex and / or difficult to access are common and often impractical to waterproof using traditional materials or fabric reinforced liquid systems.

Triflex ProFibre overcomes these issues by incorporating reinforcing fibres within our unique solvent free resin technology. With ultra-rapid cure times, even at low temperatures, and unsurpassed levels of substrate compatibility, Triflex ProFibre is simple to apply and can be installed all year round for the fast and easy waterproofing of the most complex and tricky details.

System highlights

Waterproof down to the smallest detail

Triflex ProFibre can be used stand-alone, in combination with other Triflex waterproofing, surfacing and protection liquid roofing systems, and in combination with other waterproofing technologies.

Fibre reinforced technology

Triflex lead from the front. Featuring unique fibre reinforced resin technology that allows the quick and effective waterproofing of virtually all highly complex and restricted access details and penetrations.

Self-terminating

With Triflex there is no need for termination bars as Triflex systems are fully self-terminating. By forming such a strong bond with the substrate, and thanks to its flexibility and fleece reinforcement, the system leaves no opportunity for water to permeate behind.

Cold applied, fast curing with rapid installation

Rapid curing and easy to install, Triflex allows details to be waterproofed seamlessly and quickly with the waterproofing being rainproof in as little as 30 minutes and cured in 45 minutes. Installation can be carried out all year round and Triflex ProFibre still cures quickly at temperatures down to 0°C. There is also no risk from hot works during installation as all Triflex materials are applied in a totally cold liquid form, curing to create a durable solution that lasts.

Simple application

The system could not be any simpler and easier to apply, just use a brush and any detail will be reliably waterproofed.

The complete solution

Triflex ProFibre is not only a proven stand-alone system but is also used in conjunction with other Triflex systems and other waterproofing technologies to provide a complete waterproofing solution.

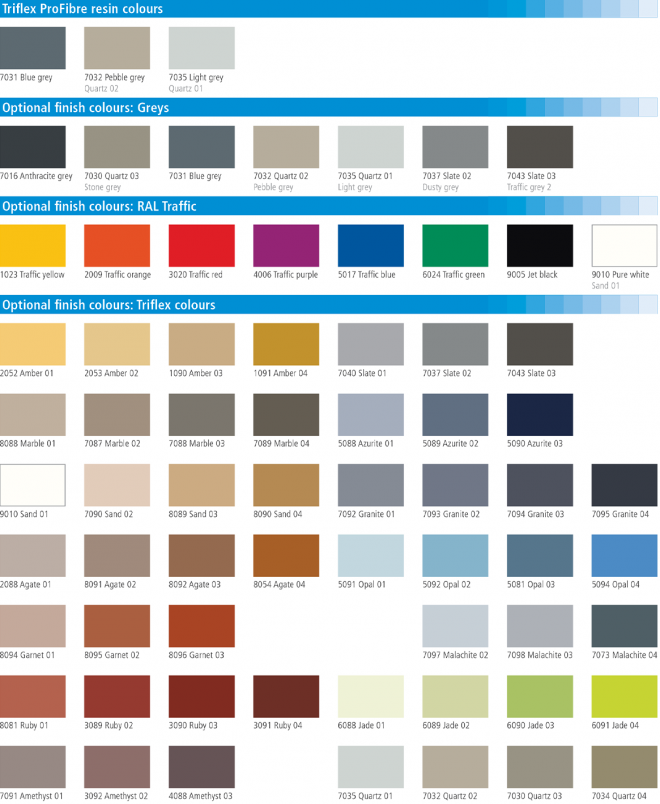

Colours and finishes

Triflex ProFibre is available in a range of standard colours or choose from more than 50 optional coloured finishes to create the perfect look - refer to Triflex colour card.

Application areas

- I-beams

- Small in situ penetrations

- Small surface mounted penetrations

- Small outlets

- Bolt heads

- Balustrades

- Cable penetrations

- Complex details and penetrations where fabric reinforcement is impractical

- Details and penetrations where access is restricted

- Metal roof eaves details

Compatible substrates

- Felt

- Asphalt

- Bitumen

- Single ply membranes

- Cementitious materials (concrete, brickwork, masonry)

- Metals and coated metals

- Plastics

- Coatings (e.g. polyurethane (PU), polyurea (PUA), polymethyl methacrylate (PMMA), GRP etc.)

- Solar reflective coatings

- Glass

- Timber

System variants

Finish colours

Triflex ProFibre is available in a wide range of standard resin colours and optional finish colours, allowing the system to be tailored to meet aesthetic and project needs with special colours being produced to order. For full details see the Triflex ProFibre colour card below.

Require an on-site survey or quote?

All installations are carried out by our network of Triflex Authorised Contracting Partners. If you have a project we can provide a free no obligation on-site survey and can put you in touch with local Triflex contractors in your area that will be able to provide you with a quote.

To organise your free on-site survey you can either complete our project enquiry form or contact your local Business Development Manager, who will be more than happy to discuss your requirements.

Triflex Authorised Contracting Partners can place orders by calling 01785 819119 or emailing orders@triflex.co.uk.

Approvals

Certified to the European standards and classifications, including:

Fire performance

- EN 13501-5: Class BROOF (t1)

- EN 13501-1: Class E

Manufacturer certification

- ISO 9001: Quality Management

- ISO 14001: Environmental Management

- ISO 50001: Energy Management