Overview

The most important part of any roof is the waterproofing system as without an effective and long lasting solution the building is vulnerable to water ingress and the risk of damage to the building fabric.

The BBA and ETA certified Triflex ProTect is an ultra versatile, highly durable roof waterproofing solution, suitable for both refurbishment and new-build, and is compatible with almost all roof build-ups and existing substrates, including single ply. Even difficult applications such as zero pitch roofs and areas that are subject to standing or ponding water pose no problem as the system does not break down under immersion in water. It is exceptionally fast curing and totally cold liquid applied, allowing installation to be completed quickly, without the use of hot works and at any time of year. With a long term proven track record and the highest levels of certification and testing, Triflex ProTect is one of the premier liquid roofing systems and sets the standard for roof waterproofing.

System highlights

Versatility and compatibility

Whether for refurbishment or new-build, Triflex ProTect is suitable for virtually all roofing applications. The significant costs, risks and disruption associated with removal of the existing membrane can be eliminated as the system is compatible with, and can be used to overlay almost all roof substrates. Even failed single ply and other membranes such as EPDM can be overlaid. Roof waterproofing made easy

Cold applied, fast curing with rapid installation

Rapid curing and easy to install, Triflex allows buildings to remain fully occupied during installation, limiting access restrictions and unnecessary disruptions to everyday activities. Installation can be carried out all year round and the system still cures quickly at temperatures down to 0°C. Being rainproof in just 30 minutes weather windows can be maximised and down time minimised. There is also no risk from hot works during installation as all Triflex materials are applied in a totally cold liquid form, curing to create a solution that lasts

Single process application

Installation time and costs are significantly reduced when compared to multi-coat, typically solvent based systems. The single process application also eliminates the risks of inter-layer adhesion issues

Self-terminating

With Triflex there is no need for termination bars as Triflex systems are fully self-terminating. By forming such a strong bond with the substrate, and thanks to its flexibility and fleece reinforcement, the system leaves no opportunity for water to permeate

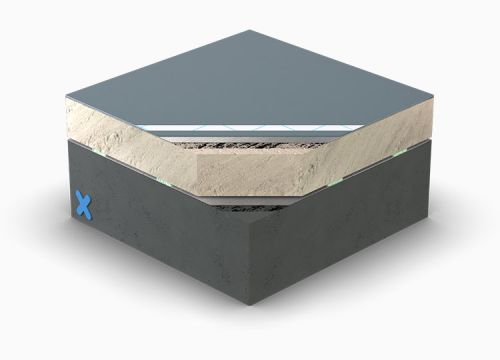

Fully reinforced technology

The unique, highly flexible Triflex ProTect resin is used with a special high tensile strength polyester fleece to ensure that high levels of movement and cracking within the structure and between substrates can be accommodated. Proven fully reinforced waterproofing technology that stands the test of time

Tried and tested

Triflex ProTect offers a complete waterproofing solution that will last for years to come. The system is not only certified and tested to the highest UK and European standards, it has also been successfully installed for more than 20 years in projects across the globe. Triflex ProTect was the first liquid applied waterproofing system to be certified under EAD 030350-00-0402 and was the first product of its type to be CE marked in Europe

Tough and durable protection

The standard Triflex ProTect system is designed for foot traffic and provides exceptional puncture resistance when compared to many alternative materials. With the option to include a heavy duty wearing layer, even the most heavily trafficked industrial roofs can be securely waterproofed and protected from damage

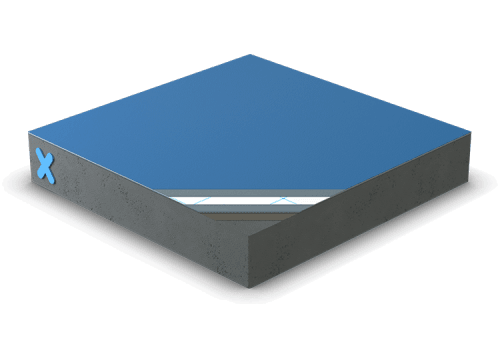

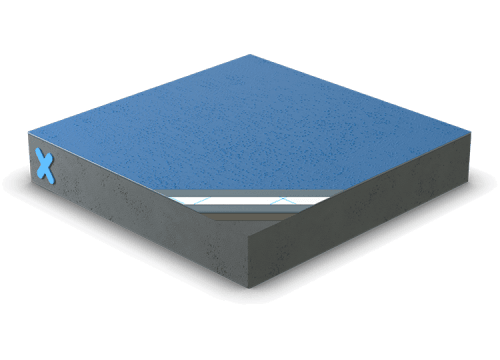

Colours and finishes

Create a design to meet your aesthetic or safety requirements with a wide range of colours and three optional finishes

Application areas

- Refurbishment

- New build

- Overlay of existing failed waterproofing systems

- Zero pitch / completely flat roofs

- Warm roofs (all insulation types)

- Inverted roofs

- Podium / plaza decks

- Buried membrane roofs

- Submerged waterproofing

- Green roofs

- Brown roofs

- Blue roofs

- Bunds / storage tanks / silos / plant rooms

Compatible substrates

- Felt

- Asphalt

- Bitumen

- Single ply membranes (e.g. PVC, PVC-P, EPDM, EVA, TPO, FPO, TPE, CPE, PIB, VET etc.)

- Cementitious materials (concrete, brickwork, masonry)

- Metals and coated metals

- Plastics

- Coatings (e.g. polyurethane (PU), polyurea (PUA), polymethyl methacrylate (PMMA), GRP etc.)

- Glass

- Timber

System variants

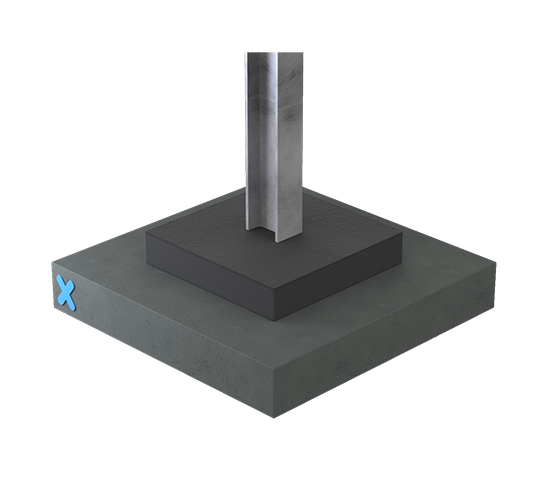

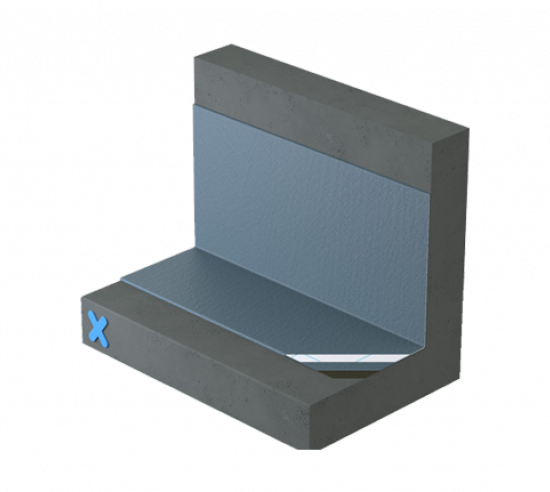

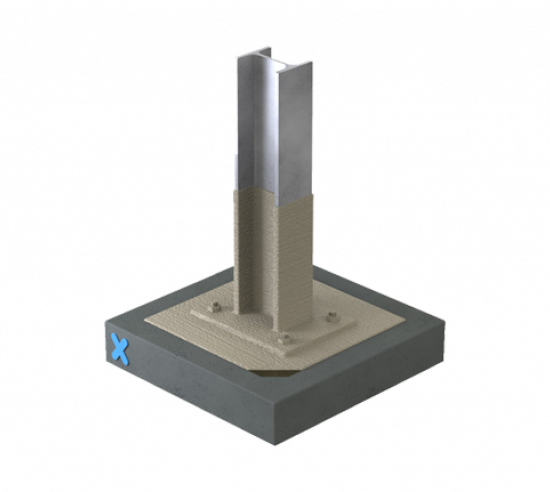

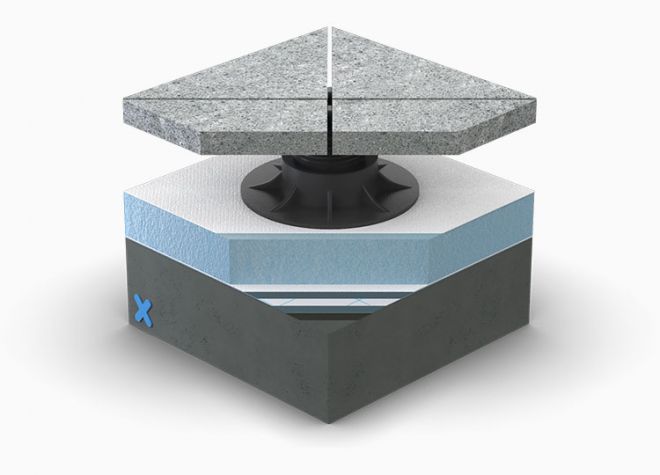

Inverted roofs

Triflex ProTect is the ideal solution for inverted roofs as the system is resistant to standing and ponding water. The system can be used with various overburden with typical build-ups including a geotextile filter fleece, extruded polystyrene (XPS) insulation, a water reducing layer and various overburden including paving and decking (with and without pedestals) and ballast.

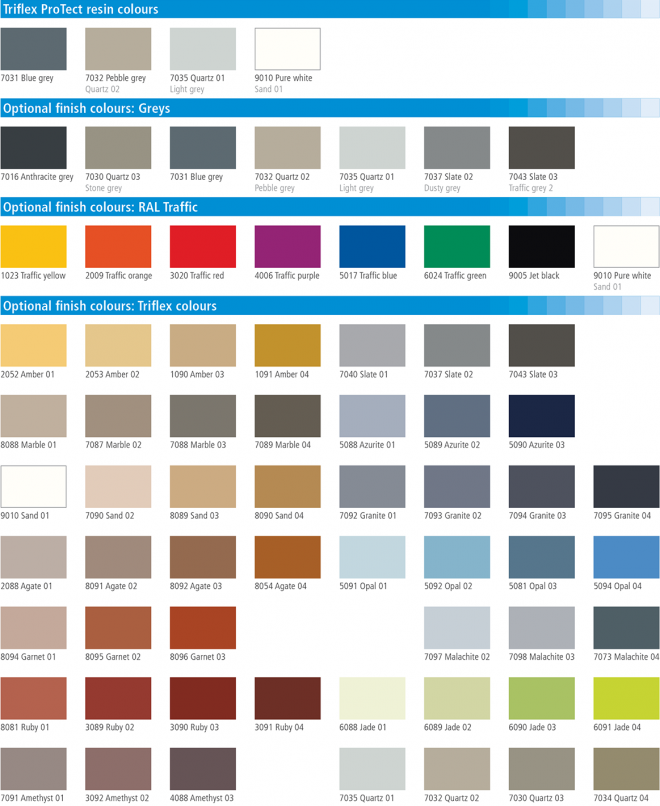

Finish colours

Triflex ProTect is available in a wide range of standard resin colours and optional finish colours, allowing the system to be tailored to meet aesthetic and project needs with special colours being produced to order. For full details see the Triflex ProTect colour card below.

Require an on-site survey or quote?

All installations are carried out by our network of Triflex Authorised Contracting Partners. If you have a project we can provide a free no obligation on-site survey and can put you in touch with local Triflex contractors in your area that will be able to provide you with a quote.

To organise your free on-site survey you can either complete our project enquiry form or contact your local Business Development Manager, who will be more than happy to discuss your requirements.

Triflex Authorised Contracting Partners can place orders by calling 01785 819119 or emailing orders@triflex.co.uk.

Certification and approvals

Full system certified, tested and approved to the highest UK and European standards and classifications, including:

Certification

- BBA

- UKTA

- EAD 030350-00-0402

- EN 1504-2 : B4.2 (-20°C) dynamic crack bridging

- FLL: Root and rhizome resistant

- EN 13948 : Resistance to root penetration

- EN 13583 : Hail resistant

Tested to

- EN 13501-5 : Class BROOF (t1), (t2), (t3), (t4)

- EN 13501-1 : Class E

- BS 476-3 : EXT.F.AA

Satisfies and contributes to satisfying

- NHBC Standards 2025

Environmental rating

- BRE / BREEAM rated

Heat resistant

- Tested to overlay at 250°C