Introduction

Built in the 1960’s, Bristol City Council’s Hartcliffe estate consists of five tower blocks, each consisting of some 60 dwellings over 11 storeys. As part of a wider multi-million pound refurbishment, roofing works for Chestnut House, Redwood House, Oak House, Rowan House and Willow House were required.

The challenge

Triflex approved contractor Rateavon Ltd were successful in contract award for the repair and improvement project tendered by Bristol City Council. Working together, a waterproofing condition survey was undertaken on the flat roofs of the five tower blocks.

It was essential to ascertain the state and build-up of the flat roofs today. Over the previous decades, different systems had been installed to the required standards of the time. Alongside a detailed visual survey, multiple core samples were taken and evaluated.

The existing build-up consisted of two warm roof systems, each a reflection of the decades in which they were installed. The existing roof waterproofing system comprises an insulated liquid system installed onto the original asphalt waterproofing. This asphalt was installed over a 25mm PUR insulation board onto a bituminous vapour control layer on structural concrete.

Core sampling indicated that the original 25mm PUR insulation was wet, with moisture build up within the original roof coverings between the 25mm PUR insulation and the underside of the 25mm asphalt. Over the lifetime of the original roof build-up (prior to the installation of the current 90mm PIR insulation and liquid waterproofing overlay), calculations showed a theoretical moisture build up could have developed.

The solution

Whilst Triflex systems can be utilised as an overlay, in this scenario the best course of action was to strip up the existing build-ups down to the concrete slab on each tower block. This enabled a new warm roof tapered scheme to be considered that delivered thermal improvements. The forward thinking Bristol City Council recognised that this was an opportunity to future proof by requiring a scheme with a U-value exceeding the current building standards.

The Triflex bespoke project specification proposed a Triflex ProTect warm roof system with tapered insulation thickness varying between 80mm and 220mm delivering a much-improved U value, and calculated condensation risk analysis demonstrating compliance with BS5250:2021.

The cold liquid applied system delivers rapid waterproofing with no hot works required. This was an important consideration for negating fire risks in residential blocks which continued to be occupied. The Triflex ProTect resins are rainproof in just 30 minutes, and fully cure rapidly even in winter temperatures, helping to ensure that the schedule of works remained on track. The speed on installation also helped minimise the length of time needed for temporary roof coverings, contributing to cost control.

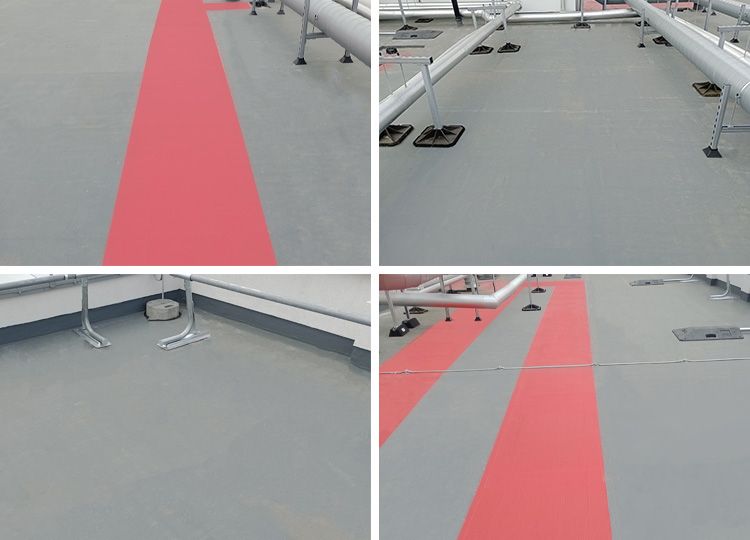

The new warm roof included improved drainage outlets and incorporation of safer maintenance access. With various plant on the roofs of each tower block, consideration for safe maintenance was a key factor. This was achieved by the application of Triflex anti-skid finish to maintenance walkways in a contrasting red colour. The durable finish ensures high quality demarcation for maintenance staff over its decades of lifetime.

Waste management

The strip up of the existing roof build-ups inevitably means there are waste management considerations. Minimising waste to landfill was a significant priority across the whole project scope. Separation of components on site was undertaken wherever possible. For example, the stripped up roofing insulation was separated out on site, and a trusted waste management company removed waste off site for recycling. Testament to a diligent approach meant that waste removal was via pallets and not skips.

The certified and durable Triflex system will provide a watertight building envelope for decades to come. In the distant future, when the system nears the end of its lifespan, it can be easily overlaid with a new Triflex system. This extends the roof’s durability, performance and life cycle even further. Triflex PMMA resins readily adhere to themselves enabling the reuse existing materials and minimise the environmental impact of construction activities.

All works were carried out to a high standard by Triflex authorised contractor, Rateavon Ltd.

“As a long standing Triflex authorised contractor we have installed Triflex systems on many different building types. The quality of the products means that they deliver confidence in the long-term watertightness of the buildings they protect. The speed of installation also means that weather windows can always be maximised, keeping project timescales in check in multi-faceted and complex projects.”

Ratevaon Ltd.